Mining Sector Rubber Solutions

Specialized rubber compounds engineered for the most demanding mining industry conditions

View SolutionsMining Sector Rubber

Mining sector rubber is specifically engineered to withstand extreme abrasion, impact, and wear conditions in mining operations. At Everest Group, we offer a comprehensive range of specialized rubber compounds that maximize equipment lifespan and component durability in the mining industry.

Our mining rubber compounds provide superior abrasion resistance, impact absorption capability, and exceptional durability in applications such as mill liners, chutes, hoppers, pumps, and mineral transport systems.

Mining Rubber Solutions

Specialized compounds for various mining applications and operating conditions

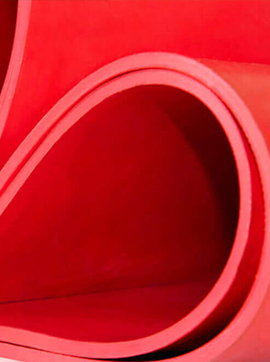

Mining Rubber Green Force

High wear and abrasion resistance for high-impact mining applications.

Explore Product ↗

Mining Rubber Orange Beat

Specifically formulated for impact and abrasion resistance in severe conditions.

Explore Product ↗

Mining Rubber Blue Gem

With special reinforcement for the most demanding applications in mining.

Explore Product ↗

Mining Rubber Hi Performance

High-performance compound with exceptional durability for critical mining equipment.

Explore Product ↗

Mining Rubber 40-45 Shore A

Controlled hardness for applications requiring specific and controlled wear characteristics.

Explore Product ↗

Mining Rubber Fullbrac

Superior protection against severe abrasion in the most extreme conditions.

Explore Product ↗

Mining Rubber FLEXIMAS

Combined flexibility and resistance for linings and specialized applications.

Explore Product ↗

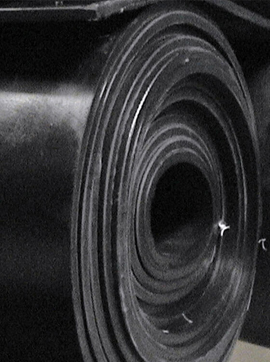

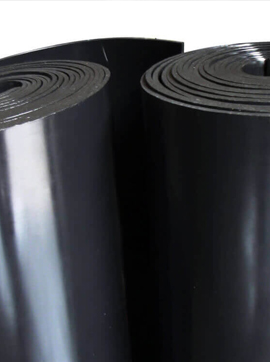

Wear-Resistant Rubber Plates

Special rubber sheets for wear protection in mining and heavy industry applications.

Explore Product ↗Mining Industry Applications

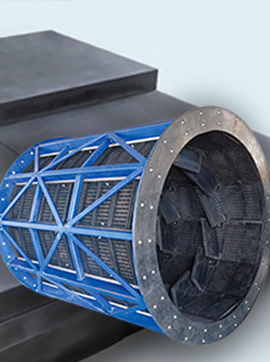

At Everest Group, we develop specialized rubber solutions for mining that adapt to the specific needs of each operation. Our compounds are designed for critical applications such as SAG and ball mill liners, transfer chutes, storage hoppers, slurry pumps, classifiers, cyclones, and mineral transport systems.

Each compound has been formulated considering factors like mineral type, particle size, flow velocity, impact, and specific chemical conditions of each mine.

Benefits of Our Mining Rubber Compounds

Abrasion Resistance

Superior protection against wear from mineral and rock friction.

Impact Absorption

Capability to withstand severe impacts from large rocks and minerals.

Extended Service Life

Significantly increases the lifespan of mining equipment and components.

Chemical Resistance

Protection against chemical reagents used in mining processes.

Reduced Maintenance

Decreases frequency of maintenance shutdowns and component replacements.

Cost Optimization

Reduces operational costs through increased durability and less downtime.

Specialized Technical Advisory

Our team of mining application engineers provides:

- Analysis of specific operating conditions

- Compound recommendations based on application type

- Design and installation guidance for linings

- Technical support throughout product lifespan

- Custom solution development

We work alongside your team to maximize operational performance and profitability.

Need Mining Rubber Solutions?

We offer specialized compounds and technical advisory to optimize your mining operations. Request a no-cost evaluation.