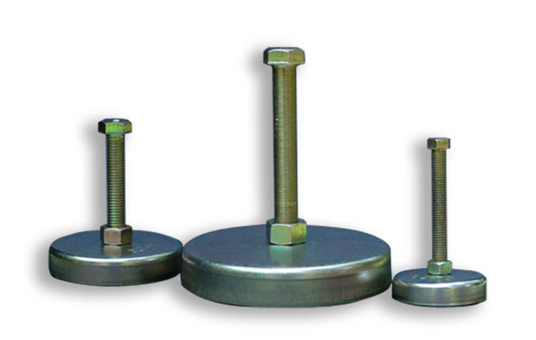

Series L Vibration Leveling Mounts

Vibration control and floor irregularity compensation in a single device

View ProductsSeries L Vibration Leveling Mounts

Series L Vibration Leveling Mounts are essential devices that offer the possibility of controlling unwanted vibrations and compensating for floor irregularities, all with a single device. Their simple construction and easy installation eliminate the need to anchor machinery to the floor, allowing for easy relocation.

The elastomeric element of the vibration leveler is resistant to oil and chemicals with practically indefinite durability, while the metallic component is tropicalized to ensure long life in different environmental conditions.

Key Technical Properties

Series L Vibration Leveling Mounts EVEREST offer unique advantages for industrial applications:

- Integrated dual function - Vibration control and irregularity compensation

- Wide range of load capacities from 250 kg to 6000 kg

- Robust construction with elastomeric element resistant to oils and chemicals

- Easy installation without need for floor anchors

- Tropicalized metallic component for greater durability

- Unaffected by weather, chemicals, grease, and oils

- Zero maintenance cost and long service life

Ideal for lathes, mills, granulators, presses, stamping machines, plastic and rubber injection molding machines, and any equipment requiring precise leveling and protection against vibrations.

Benefits of Series L Vibration Leveling Mounts

Irregularity Compensation

Absorb height differences in machinery relative to the floor, ensuring a level base for optimal operation.

Vibration Control

Eliminate unwanted vibrations generated by industrial equipment, protecting both machinery and structures.

Easy Relocation

Allow equipment relocation by simply lifting, moving, and placing it in its new position.

Element Resistance

Unaffected by weather, chemicals, grease, and oils, ensuring operation in demanding industrial environments.

No Anchoring Required

Eliminate the need to fix machinery to the floor, reducing installation costs and allowing greater flexibility.

Maintenance Savings

Zero maintenance cost and practically indefinite durability of the elastomeric element.

Industrial Applications

Specific uses of Series L vibration leveling mounts

Lathes

Leveling and vibration isolation in lathes of different capacities and sizes.

Mills and Granulators

Vibration control in mills, granulators, and processing equipment.

Presses and Stamping Machines

Impact and vibration absorption in presses, stamping machines, and embossing equipment.

Injection Molding Machines

Plastic and rubber injection molding machines, ensuring stability during the process.

Pumps and Compressors

Pumps, compressors, and rotating equipment that generate vibrations during operation.

Printing Equipment

Printing presses and graphic equipment requiring precision and stability.

Technical Specifications - Series L

Characteristics and capabilities of Series L vibration leveling mounts

| MODEL | D (mm) | A (mm) | SCREW D (mm) | MAXIMUM LOAD (kg) |

|---|---|---|---|---|

| DL-70 | 70 | 24 | 11 | 250 |

| L-120 | 110 | 31 | 16 | 1350 |

| L-160 | 160 | 40 | 19 | 3500 |

| L-200 | 208 | 45 | 25.4 | 6000 |

General Characteristics

Design Advantages

Installation and Use

Guide for proper installation and use of Series L Vibration Leveling Mounts

Area Preparation

Ensure the surface where the vibration leveler will be placed is completely horizontal to avoid displacement. Clear the area of any obstacles.

Positioning

Place the vibration levelers at the equipment support points, typically at the four corners. No floor anchoring is necessary.

Equipment Placement

Place the machinery on the vibration levelers. The device will automatically absorb height differences relative to the floor.

Relocation (when necessary)

Want to relocate your equipment? Simply lift it, move it, and done! Vibration levelers allow for easy relocation.

Need Series L Vibration Leveling Mounts?

We offer Series L vibration leveling mounts for different capacities (250kg to 6000kg) and industrial applications. Specialized technical consulting.