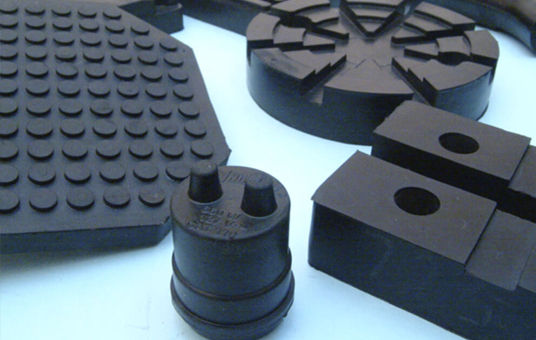

Molded and Extruded Rubber Profiles

Custom rubber solutions for industrial and commercial applications

View ApplicationsMolded and Extruded Rubber Profiles

Molded and Extruded Rubber Profiles are elastomeric components manufactured through compression molding, injection molding, or extrusion processes, designed to fulfill specific functions in various industrial applications.

From seals and gaskets to structural components, we offer customized solutions using different rubber compounds to meet the most demanding requirements.

Technical Characteristics

Molded and Extruded Rubber Profiles offer unique advantages for industrial applications:

- Custom designs according to customer specifications

- Wide range of materials for different applications

- High dimensional precision in each manufactured part

- Excellent resistance to severe environmental conditions

- Long service life and proven durability

- Versatility of applications across multiple industries

- Optimized costs based on volume and complexity

These components are essential to ensure optimal performance of equipment and systems in diverse industrial applications.

Manufacturing Processes

Specialized technologies for each application

Compression Molding

Ideal for medium to large parts and low production volumes.

- Structural parts

- Large components

- Prototypes

- Short runs

Injection Molding

Perfect for complex parts and high production volumes with high repeatability.

- Complex parts

- High precision

- Long runs

- Intricate geometries

Extrusion

Optimized for continuous profiles with constant cross-section in variable lengths.

- Continuous profiles

- Linear seals

- Long seals

- Mass production

Types of Profiles and Molded Parts

Specialized designs for every need

Sealing Profiles

Designed to create hermetic barriers against water, air, dust, and other elements.

Damping Profiles

Absorb impacts, reduce vibrations, and protect surfaces from damage.

Structural Profiles

Provide structural support and functionality in complex assemblies.

Fluid Handling Profiles

Specialized for applications involving liquids, gases, or hydraulic systems.

Available Materials

Elastomeric compounds for every application

Neoprene

Weather, ozone, and oil resistant

Silicone

High temperature and food grade

EPDM

Excellent weather resistance

Nitrile (NBR)

Resistant to oils and fuels

Viton (FKM)

High temperature and chemical resistance

Natural Rubber

Excellent flexibility and resilience

Butyl

Low gas permeability

Special Compounds

Formulated according to requirements

Industrial Applications

Solutions for various industrial sectors

Automotive

- Door and window seals

- Engine and transmission gaskets

- Suspension components

- Acoustic insulation

Industrial

- Machinery gaskets

- Process equipment seals

- Chemical-resistant components

- Industrial bumpers

Construction

- Window and door profiles

- Expansion joints

- Facade seals

- Thermal and acoustic insulation

Electronics

- Enclosure seals

- Electrical insulation

- Device components

- Moisture protection

Medical

- Device components

- Medical equipment seals

- Sterile gaskets

- Biocompatible materials

Food Processing

- Food-grade components

- Processor seals

- Kitchen equipment gaskets

- Non-toxic materials

Advantages of Our Molded and Extruded Profiles

Custom Design

We develop profiles and molded parts according to your exact specifications and technical requirements.

Wide Range of Materials

We work with various elastomeric compounds to satisfy any application.

Guaranteed Quality

Strict quality controls at every stage of the manufacturing process.

Rapid Prototyping

Capability to develop prototypes in reduced timeframes for validation.

Timely Delivery

Commitment to agreed delivery times for your projects.

Technical Consulting

Specialized technical support to select the optimal material and process.

Need Custom Molded or Extruded Rubber Profiles?

We have the experience and capability to develop custom elastomeric solutions for your specific application.